NUS

Transforming Chemical Synthesis through Sustainable Catalysis and Radical Chemistry

Chemical manufacturing is one of the key pillars of the global economy and plays a crucial role in the modern human society. Chemical catalysis is an indispensable tool to promote reactions that enable access to various classes of chemicals, ranging from small-molecule medicines to polymeric materials. Despite considerable advances made in this area, much of it depends on the use of exorbitant and scarce noble metals (such as palladium) to prepare catalysts. Considering the rapidly dwindling abundance of precious metals, this approach cannot continue much longer. More industries have begun an earnest search for sustainable and cost-effective alternatives that are not subject to devastating fluctuations caused by price speculation, a well-known attribute of the precious metal market.

Furthermore, such precious metal-derived catalysts are only capable of mediating a limited range of reactions. As a result, longer synthetic sequences often have to be employed to convert a starting material to the desired target product. Unfortunately, each step in a chemical synthesis process consumes energy, resources and time, and generates waste (spent carbon-based solvents and other by-products) that has to be treated or incinerated. Based on the National Environment Agency (NEA) statistics, about 27,500,000 litres of spent solvents are collected annually in Singapore and subsequently used as supplementary fuel for toxic waste incinerators! Consequently, this leads to more CO2 and other toxic emissions that contribute to global warming, climate change, rising sea levels and other undesirable environmental problems. A lengthy and inefficient chemical synthesis process also means that manpower costs inevitably rise due to a greater demand for workers to carry out the tasks.

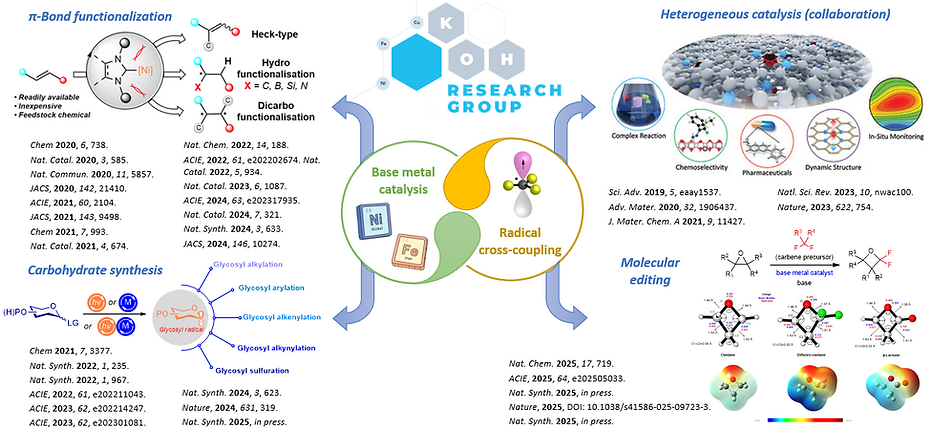

To address the aforementioned challenges, our group focuses on the research of sustainable catalysis, where we develop catalyst systems derived mainly from earth-abundant base metals such as iron, nickel and copper. Our efforts have led to the discovery of new multi-tasking and energy-efficient catalysts that are capable of mediating unprecedented chemical transformations, which significantly enhance the efficiency and shorten the steps required to access a target chemical product. These catalysts are employed in innovative approaches to transform cheap and abundant feedstock chemicals to value-added products with lower environmental footprint.

Ongoing topics of interest include:

(a) Discovery of skeletal editing transformations to access cyclic functional molecules.

(b) Development of peripheral editing transformations for site- and stereoselective functionalization of carbohydrates.

(c) Photochemical, electrochemical and/or base metal-catalyzed synthesis of drug-like molecules.

(d) Discovery of reaction systems that engage radicals in cross-coupling transformations.

(e) Development of catalytic regio- and stereoselective alkene functionalization reactions.

(f) Design of new heterogeneous single-atom catalysts for liquid-phase organic synthesis (collaboration with materials chemists).

(g) Elucidation of reaction mechanisms via mechanistic and computational studies (collaboration with computational chemists).

(h) Plastic waste upcycling using base metal catalysis (collaboration with materials chemists).

We cordially welcome collaborations in all areas of research including total synthesis, computational chemistry, AI/ML, chemical biology and materials science.

We aspire to be among the top organic chemistry research groups in the world. Students working in the Koh group can expect to be mentored on the process of identifying important problems in chemical synthesis, trained in fundamental research and presentation practices, and groomed to think critically, creatively and independently at the highest level. We work in a close-knit environment where every member has fun and contributes to the success of one another. Members who have worked in our group have went on to establish their own careers and become successful in their own right.